Production and Technology

Production Process

High Quality Products Respecting Mankind and Environment.

Norman Group, with its 7 divisions and a production of 14 million seamless items, boasts nowadays a remarkable position in the mentioned field.

This strategic organizational choice requires that all phases of the supply chain are handled internally (from design to production to distribution for sale) and allows for greater control of the quality of the product by shortening the production chain.

Norman Group has been vertically integrated for over 25 years.

Each step – from yarns to finished product – is organized and controlled through various tests which guarantees high quality and the absence of toxic substances for people and environment. Production in each division of Norman Group is regulated in order to respect human rights and environment.

High-Quality Raw Material for Innovative Products.

Norman Group constantly researches innovative raw materials and high-quality yarns, looking for international partnerships and filing advanced patents. With the collaboration of the worldwide most important producers in this field, Norman Group uses innovative yarns as Fulgar, Lycra-Invista, Creora-Hyosung, Ashay Kasey, Dryarn, Borgolon, Meryl Fibers, Nytex, in addition to precious microfibers and natural fibres as cotton, bamboo, wool, viscose and cashmere. All these raw materials perfectly suit production requirements of the Company and experimentation to develop single items or complete collections more and more refined. Seamless technology keeps on innovating and specializing: this allows Norman Group to be even more competitive, never failing in respecting Italian and European standards, certifications and regulations.

Productions Steps.

Production of seamless items in Norman Group follows different steps which undergo strict quality tests.

Knitting

This step takes place in the new knitting room which can count on 168 advanced circular SANTONI machines, from 13” to 20”.

Raw Product Ironing and Control

This operation is carried out internally, piece by piece, through automatic machines with infrared rays specifically studied by Norman Group.

Dyeing

The dyeing step takes place in the dye-works owned by the Company. This process is monitored with the utmost care and attention: all the dyes and softeners must fully comply with the STANDARD 100 by OEKO-TEX® to safeguard consumers health and environment.

Sewing

This step is carried out internally in the workshops owned by Norman Group situated in Czech Republic, Romania and Serbia.

Dyed Products Ironing

During this phase front and back of each piece is controlled using automatic CORTESE 832 machines equipped with steam process.

Printing

For this operation Norman Group employs a transfer printing press MONTI. All-over printings are realized with superb quality results thanks to a printing system developed by the Company itself.

Labelling

Each item is provided with a transfer labelling, which does not need any sewing and efficaciously resists to washings.

Packaging

Depending on the different requirements, each item is packed in a little box, in a transparent envelope or set on a hanger. After applying the corresponding barcode, each product is ready to be shipped.

Patents and Special Finishings

“I-CONE”: is the patent designed to make seamless production even more sustainable.

“I-CONE”: is the patent designed to make seamless production even more sustainable.

With “I-CONE”, we are able to reduce textile waste from processing our products, reducing waste from 64% to 100%, depending on the type of garment. For high sustainability in terms of waste reduction, the application of the patent is currently integrated on most of our production lines.

I-CONE advantages

- Applicable to any fabric

- Up to -82% of total waste

I-CONE - THE PATENT FOR ELIMINATING WASTE

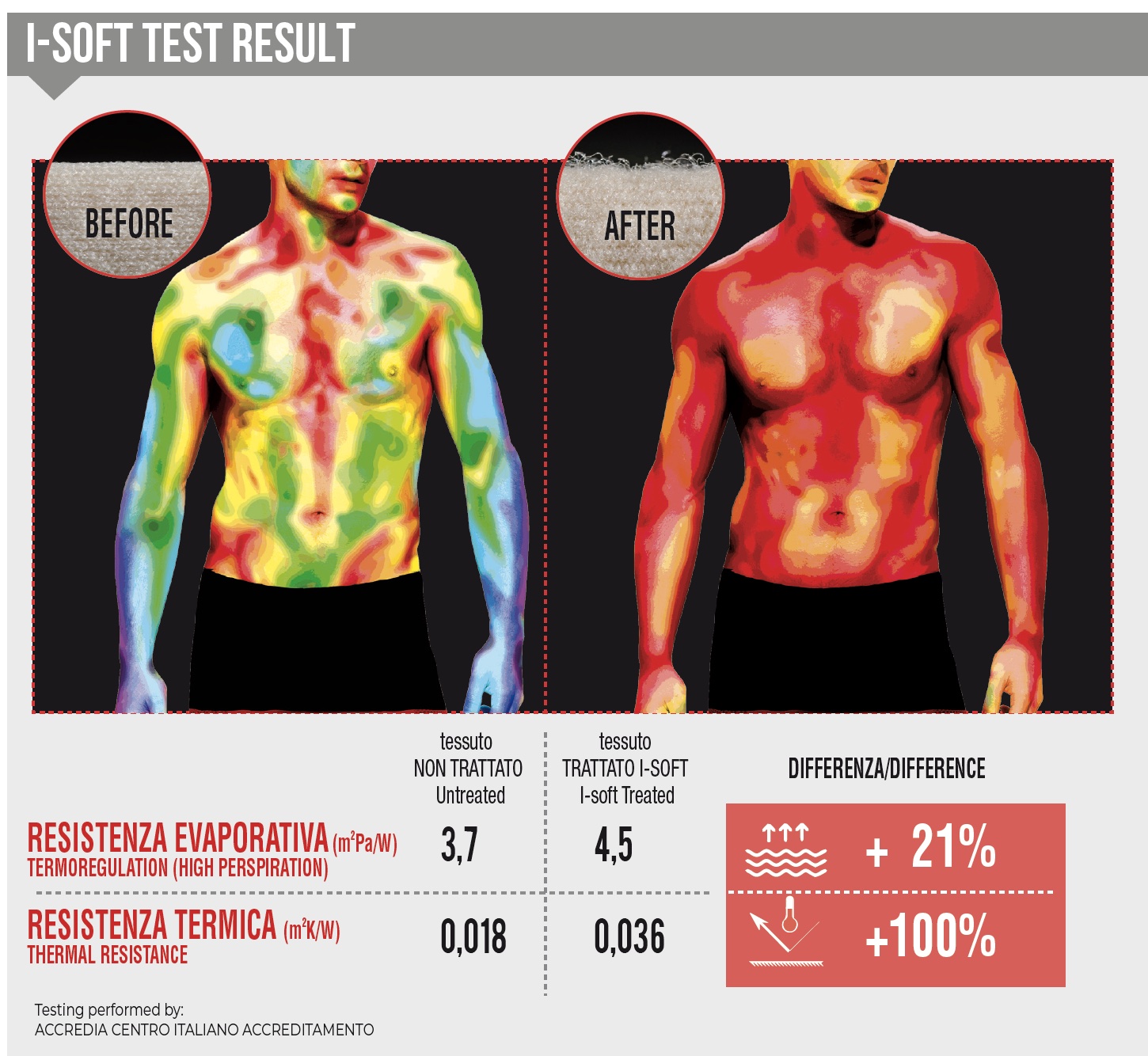

I-SOFT is the innovative patent of Norman Group that revolutionizes the use of technical fibers in seamless. It is a heat treatment that, applied to any fabric, gives warmth, softness and consistency comparable to the characteristics of natural fabrics.

I-SOFT creates an insulating and thermoregulatory barrier that keeps the temperature and humidity constant.

I-SOFT is able to increase the performance of the garment in terms of moisture absorption, breathability and thermoregulation. The performance of fabrics treated with I-SOFT remains intact throughout the life of the garment: unlike topical treatments, in fact, I-SOFT modifies the fiber; its properties, therefore, do not diminish with washing or wear.

To guarantee the best results, I-SOFT is used as the inner layer of the garment – the one closest to the body – in order to provide efficient insulation. Norman Group uses it successfully for knitwear, leggings, sportswear and more generally for all those garments to be used in contact with the skin in case of low temperatures.

I-SOFT advantages

- Applicable to any kind of fabric

- Fabric performances unchanged in time

- Maximum softness

- Warm touch

- Comfortable on the skin

I-SOFT IMPROVES THE THERMAL PERFORMANCE OF SYNTHETIC FIBRES

I-BAND, Norman Group’s exclusive patent, gives seamless garments the fit and shape of cut and sewn, while maintaining the advantages of seamless technology: essential seams, optimal elasticity and superior comfort.

The special oblique finish of I-BAND adds fabric to the back of the garment, ensuring an ergonomic fit, freedom of movement and unprecedented comfort. This translates into a flattering silhouette and long-lasting comfort, ideal for any activity.

The application of I-BAND is possible on a wide range of seamless garments (t-shirts, leggings, underwear, etc.) and on any composition of yarns. This means choosing the fabrics that best suit your needs, without compromising fit and comfort. In fact, I-Band improves the construction of the garment, enhancing the characteristics of the fabrics used.

I-BAND advantages

- Improved performances

- Improved wearability

- Applicable to any fabric

- Performances unchanged during time

I-BAND IMPROVES THE FIT OF GARMENTS

Special Finishing

In addition to usual treatments, Norman Group offers a wide range of particular manufacturings and special finishings.

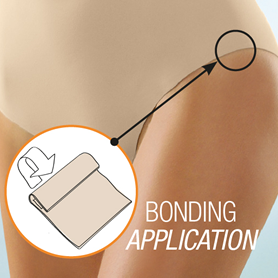

Particular manufacturing

Le Particular manufacturing includes: a special system for bonding finishing, characterized by the total absence of sewing that makes edges ultra-flat, invisible under garments and extremely elastic; an anti-slip system created with silicone, adherent and elastic, which can follow fabric movements without breaking; unlimited application of prints through heat transfer print, from small inserts to a wide range of localized or all-over prints.

Special finishing

Available special finishing proposed by Norman Group includes waterproof treatment, which guarantees excellent performances maintaining unchanged the texture, and perfumes treatment, that is the application of microencapsulated essences which gives garments a pleasant and long-lasting perfume.

Bonding

Invisible finish through heat-sealed adhesive film.

Stop&Fix

Silicone tape applied inside the strap which guarantees adhesion and anti-roll of the chief.

Quality and Certifications

An Ethical Production of High Quality

Norman Group follows an ethical production process which guarantees the respect of fundamental rights of workers but also of environment. In this way, the Company can offer innovative products of high quality, but also ethically correct, since they’re realized respecting principles of moral legitimacy, equality, parity and transparency to protect mankind, health and environment.

In particular, Norman Group

Produces respecting human and workers rights. The Company doesn’t exploit child labour and respects workers safety, healthiness of workplace, minimum wage and working time.

Pays extreme attention to quality of products, testing colour fastness, resistance to washings, perfect wearability. The Company can count on a dedicated Quality Control team that guarantees the respect of the highest quality levels.

Avoids the use of toxic substances which could damage people and environment and continuously tests its products to assure the total absence of damaging elements.

Employs exclusively certified raw materials and accessorizes and eliminates production and industrial waste following strict rules for the environment respect.

Applies the highest ethical and environmental standards based on moral legitimacy, equality and parity, transparency, honesty and impartiality to protect workers, their health and work place.

Environment

Attention to Environment for an Eco-Friendly Production.

Norman Group has lately made important investments in environment sustainability. In particular, the headquarter in Castel Goffredo (MN) is provided with a Led lighting system which guarantees a remarkable energetic saving. Dyeing and finishing departments count on a new generation furnace that allows to save gas for the production of steam and hot water. Moreover, Norman Group is introducing a new dyeing technique that can save the 40% of water compared to the current annual consumption of 150.000 cubic meters. Lastly, knitting machines are studied to recover energetic and thermal resources, reducing energy used for heating.

Our Commitment in Favour of the Environment.

- Use of recycled paper packaging.

- Reduced direct/indirect emissions in air and water.

- Reduced water consumption.

- High efficiency in energy use.

- Use of the greatest technologies available on market.

- High efficiency in waste recycling.

- High efficiency in recycling water of production.

- Educated staff.

- Transparency during production steps.